Table of Contents

ToggleWhat is PPE?

Personal protective equipment, also referred to as PPE, is equipment to reduce exposure to workplace hazards that could cause serious injuries and fatal incidents. These hazards may be electrical hazard, radio-logical hazards, mechanical energy, fall hazard or chemical.

PPE Importance In Workplace

Protective equipment are designed to be the first defense line against hazards and human mistakes in workplace. So its important to wear proper equipment for the job you are involved in.

Poorly fitting items are not expected to provide the proper protection. Even if you don’t feel very comfort never put your self at risk. Always wear your items. Using proper and well fitting items keeps you protected.

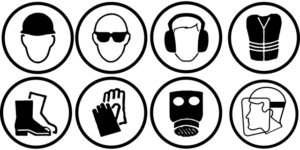

Personal protective equipment example

PPE may include items for different jobs i.e PPE for electricians and workers are not the same as welding workers. This difference between jobs requirements of protective equipment is so logic as the hazards that electricians face are not the same hazards that welders face. Hereunder protective equipment examples.

Gloves

Are used for hand protection against chemical, electrical and mechanical hazards. Always choose the right gloves for the job. Not all gloves are suitable for all jobs. For example electrical work needs isolated gloves with max. voltage suitable for the voltage of the power system.

- Face guard.

We always pay attention to eye protection by wearing goggles, This is for eye protection against splashes, flying particles and flash hazards at workplace. For more safety and protection face guard or face shield is used. Face guards provide a higher protection level than goggles. Always use face shield with goggles to adequately protect an employee from flying parts or objects, and large particles.

- Glasses.

Are the main eye protector in workplace. As mentioned above goggles are always used even with face shield.

- Safety boots or shoes.

These are a special type of shoes which are designed to protect your feet against heavy loads hazards.

Also safety shoes are anti slip and electricity isolation too. They provide additional electrical safety when working in electrical jobs as they makes your resistance to ground higher.

- Safety vest.

High visibility safety vests are required in workplace where are vehicles,cars and heavy tractors hazard, workers must be seen. There are many of roadside distractions in workplace, these distractions can make it hard for drivers to even notice that you are there.

Reflective safety vests helps well specially at night shift of work and at dusty days when visibility is poor. Here the vest grabs the driver’s attention and focus

- Coverall clothing.

Are a one piece protective clothing for heavy manual work at workplace and workshops. Some industries use the coverall to protect workers against heat, fire, chemicals or water.

- Safety harness

Are a protection personal protective against fall from heights. By wearing the harness you are able to attach themselves to a stationary object, In case of fall the harness prevent you and safe you.

What is Safety Harness, And their uses?

- Mask.

- Hard hat is the basic PPE for head protection.

When I was fresh graduated and joined my first industrial job I asked my self why should I wear this hard hat? While I’m in the location of work there were metal pipelines over my head and suddenly I hit a pipeline with my hard hat. I realized the importance of wearing protective equipment.

- Earplugs or muffs

Earplugs or muffs are so important for those who are working with high sound equipment and places. They are made of sound-attenuating material.

- Respiratory

Respiratory Protective Equipment (RPE) is that type of Protective Equipment used to protect against the workplace air hazardous substances.

- Waterproof hood for outdoor working in rainy places and for workers.

- Zero hood face warmer is necessary at cold workplaces to warm the face.

Additional tips for Personal protective equipment.

- Always use the right PPE for the job. If you don’t know the exact hazards in the job don’t hesitate to ask for help.

- If you are a work owner conduct regular meetings and training for workers to make sure they have the expected knowledge about protective equipment in they workplace.

- Make sure to inspect your safety before using them to ensure that they are in a good condition. Remember “Poor items provide poor protection”.

- Always store your reusable items in dry and clean place for the next usage.

- Not all items are reusable, Some safety items are one time use. Never use them twice.

- Personal protective items are for personnel use only, Don’t share them with coworkers.

- There’s no exceptions in wearing your items, i.e shot time jobs also have hazards and should be controlled.

- Wearing your full protection items not mean that the hazards gone. The hazard still there and need a chance to attack and hurt you hard.

- Supervision and punishment are not the only way to keep workers wearing their items, safety culture should be a part of all employees work day.

How to encourage employees to wear their safety items?

You can’t 100% force all employees and workers to be committed to safety rules and wear their items. But you should make your best to make them know the importance of safety for them and for the work productivity. The following tips could help to encourage employees to wear their safety items.

- A clear safety rules and policy should be well known for all workers from day one at the place.

- A regular inspection and follow up in workplace for any safety violations regarding PPE wearing.

- Monthly bet safety performance reward to be given for the best committed worker.

- Also punishment rules for those who are not committed to protective items.

- A good training program should help to enhance the safety culture.

- All required items must be available all the time. And every worker must have his own items.

- All supervisors and managers must do encouragement and enforcement to make all workers committed to safety PPE.

- Hazard analysis is important to ensure that you provide the correct safety items.