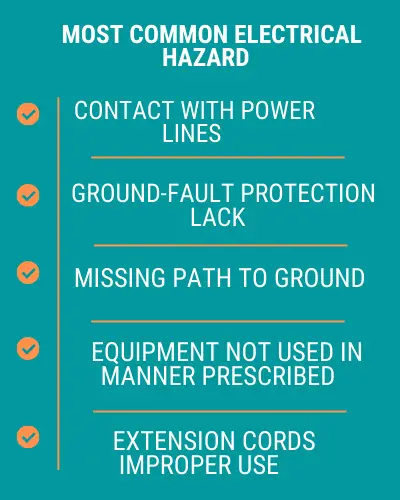

Identifying electrical hazard is the first protection line against it. Many workers are unaware of the potential electrical hazards at workplace. This may cause them many serious injuries or fatality. A regular safety inspection for electrical hazards and faults is important to control any potential hazard. A simple Electrical hazard identification check list should has the most common electrical hazard at workplace which are:

Direct contact with Power Lines

We are not talking about human direct contact with hands or body, But we mean the direct contact while the worker is thinking that he is safe and away of the live power line.

Power lines and underground cables at work site are especially hazardous because they may have high voltages. Power lines may cause electrocution without direct contact because of the electrical field around the line.

How to Avoid Hazards?

- Before any job check for power lines and underground cables signs and warning posts.

- Contact electrical specialists and ask about the underground cables at the site.

- If the location has power lines, stay away 10 feet of it.

- When using ladder, only use isolated or non conductive ladders.

- Any work around or near underground lines, an authorized electrician should watch the work for safety purpose.

- If possible, Isolate underground cables and overhead power lines as an electrical safety precaution.

- Assume that overhead lines are energized, You can’t see the electrical energy.

Path to Ground Missing or Discontinuous

Electrical grounding for electrical equipment and metallic parts around it is essential. Lack of grounding or if the grounding path is discontinuous any fault current will pass through human’s body when toughing the faulty equipment.

The main job of the electrical grounding is to provide a safe path for the fault current away from the worker’s body. This because electrical current will choose the lower resistance path to flow t ground.

Electrical hazard identification of grounding path lack

Electrical hazard identification of grounding path lack need both visual inspection and measurement with grounding grounding measurement clamp.

Electrical equipment can go hazardous while the visual inspection can’t tell so, because the grounding cable is connected. This is because the grounding system depends on the resistance of the path to the ground which can affect by soil conditions i.e dry soil has higher resistance than wet soil. So don’t rely on the visual inspection.

How Do I Avoid this Hazards?

- Connect all electrical equipment to ground through two parallel cables.

- Measure the grounding resistance after connection and make sure its value is less than 5 Ohms.

- Inspect and measure the grounding system in regular basis to make sure that the path to ground is continuous and its resistance is with in limits.

- Visual inspect all electrical equipment before use, any damage must be repaired first.

Ground fault Protection (GFCI) lack

If the equipment is not grounded and the insulation of its electrical cord or parts get damaged, Then the worker will get chocked unless a proper ground fault protection is set. GFCI or ground fault circuit interrupter trips in case of ground faults and protect the worker from the fault current.

How to avoid hazards?

- Use GFCI for all receptacles.

- Visual inspect all equipment before use and check any:

- damage or frayed cords

- missing ground prongs

- cracked tool casings

- Don’t use any defective tool and apply a warning tag to it until repair or replacement.

- Use double insulated tools and equipment.

- Insure GFCI is working correctly by following manufacturers’ testing procedure recommendation.

Equipment Not Used in Manner Prescribed

Safety features of an equipment depend on the proper use of it, i.e you can’t depend on safety features built in an electrical equipment If you use it away of its designed work conditions.

For example:

- Using an electrical equipment or a tool outdoors while it is labeled for indoor use only.

- Using extension cord for heavy loads that are larger than its current capacity. This may cause short circuit and fire.

- Using fuses or circuit breakers for over-current protection with wrong rating.

- Connecting electrical equipment on wrong voltage. For example connecting a 110V tool to a 220V outlet.

- Using modified tools, e.g.:

- removing ground prongs.

- removing insulation.

- removing face plates.

How To Avoid Hazards?

- Stick to the manufacturer instructions of use.

- Read the new equipment nameplate voltage and rating power.

- Don’t overload cords and outlets.

- When selecting circuit breakers and GFCI’s check its ratings and make sure it is proper for the equipment which will work through it.

Extension and Flexible Cords Improper Use

Using extension cords in workplace should be reduced as possible. Any damaged insulation or expose wires, can create hazardous conditions. As using extension cords at workplace sometimes is the only solution, so safety tips for using these extensions are listed below.

Safety tips for using extension cords:

- Visual inspect any used cord before connecting it. Check its insulation and condition.

- Use connection accessories, devices, and fittings for good connection.

- Don’t lay the cord on ground in the way of heavy truck and cars. Cars and trucks can damage the insulation and cause short circuit.

- Make sure that the cord current carrying capacity is suitable for the load.

- Use only three wire cords to connect the ,load to grounding.

- Pulling on the plugs is the right way to remove cords from receptacles not by the cords.

- Regular inspect all extension cords at the site to ensure its condition and repair or remove any damaged cords.

conclusion of electrical hazard identification

- A good maintenance and inspection program can prevent electrical hazard at workplace.

- Fuses and circuit breakers must be designed to safely handle the load.

- Read and follow manufacturer instructions of safe use of the equipment.

- Repair or replace any damaged tool or equipment.

- Reduce the use of extension cords as possible.

- Crane, heavy truck and ladders are commonly to get in direct contact with power lines.